Regarding manufacturing a product, having a clear and detailed plan is key to success. This is where a Bill of Materials (BOM) plays a crucial role.

What Is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a detailed list of all the materials, components, and instructions required to manufacture a product. It serves as a production roadmap, outlining the steps and resources needed to create the final product.

A BOM typically includes information such as part numbers, descriptions, quantities, and specifications for each item needed in the manufacturing process.

Why Use a BOM?

Using a Bill of Materials (BOM) offers several benefits for manufacturers:

Enhanced Production Planning

Having a BOM in place enhances production planning by providing a detailed list of materials and components required for production. This allows manufacturers to plan their production schedules more effectively, ensuring that all necessary resources are available when needed. Manufacturers can avoid delays and optimize their production processes by knowing exactly what materials are needed and in what quantities.

Accurate Cost Estimation

A BOM plays a crucial role in accurate cost estimation for manufacturing a product. By listing all the materials and components required, along with their quantities and specifications, manufacturers can calculate the total cost of production more accurately. This information is essential for budgeting, pricing strategies, and determining the overall profitability of a product. With a detailed BOM, manufacturers can identify cost-saving opportunities, optimize material usage, and make informed decisions about production costs.

Efficient Inventory Management

Efficient inventory management is another key benefit of using a BOM. By specifying the exact quantities of materials needed for production, a BOM helps in managing inventory levels more effectively. Manufacturers can avoid overstocking or understocking issues, reduce excess inventory carrying costs, and ensure that the right materials are available at the right time. This leads to improved supply chain efficiency, reduced lead times, and better control over production costs.

Improved Quality Control

Quality control is essential in manufacturing to ensure that the final product meets the required specifications and standards. A BOM plays a critical role in quality control by providing a detailed list of materials and components needed for production. By following the specifications outlined in the BOM, manufacturers can maintain consistency in product quality, identify any deviations from the standard, and take corrective actions to address quality issues. This leads to higher customer satisfaction, fewer product defects, and a stronger reputation for quality and reliability.

Effective Communication

Communication between design and production teams is crucial for the success of any manufacturing operation. A BOM facilitates effective communication by serving as a common reference point for all team members involved in the production process. Designers can convey their requirements to the production team through the BOM, ensuring that everyone understands the materials, components, and specifications needed for manufacturing. This helps in avoiding misunderstandings, errors, and delays, leading to smoother production processes and better collaboration between teams.

Types of Bills of Materials

There are different types of Bills of Materials (BOM) that can be used depending on the specific requirements of a manufacturing process:

Single-Level BOM

A single-level BOM lists all the components and materials needed to manufacture a product without detailing sub-assemblies. This type of BOM provides a straightforward list of all the materials required for production, making it easy to understand and follow. Single-level BOMs are commonly used for simple products that do not require complex assembly processes or hierarchical structures.

Multi-Level BOM

A multi-level BOM breaks down the BOM into hierarchical levels, detailing sub-assemblies and components within each level. This type of BOM is useful for products that have complex structures with multiple levels of assembly. By organizing components into hierarchical levels, manufacturers can better understand the relationships between different parts and how they come together to create the final product. Multi-level BOMs help in planning production processes, managing inventory, and coordinating assembly tasks more effectively.

Manufacturing BOM

A manufacturing BOM focuses on the materials and components needed for the actual manufacturing process, excluding packaging materials and other non-production items. This type of BOM is specific to the production phase of a product and helps in planning manufacturing operations, optimizing production workflows, and ensuring that all necessary materials are available for assembly. Manufacturing BOMs are essential for improving production efficiency, reducing waste, and streamlining manufacturing processes.

Engineering BOM

An engineering BOM includes all the components and materials needed for the design and engineering of a product, including prototypes and testing materials. This type of BOM is used during the product development phase to specify the technical requirements, design specifications, and testing criteria for a new product. Engineering BOMs help in translating design concepts into physical products, identifying the necessary components for prototyping and testing, and ensuring that the product meets the desired performance standards. Engineering BOMs are essential for innovation, research, and development projects.

Who Prepares a Bill of Materials?

A Bill of Materials (BOM) is typically prepared by a team of engineers, designers, and production planners who have a deep understanding of the product and its manufacturing requirements. This team collaborates to create a detailed list of all the materials, components, and instructions needed to bring the product to life.

Role of Engineers in BOM Preparation

Engineers play a key role in preparing a Bill of Materials (BOM) by providing technical expertise and design specifications for the product. They are responsible for identifying the materials and components required for production, determining the quality standards and tolerances, and ensuring that the product meets the desired performance criteria. Engineers work closely with designers to translate product requirements into specific components and materials listed in the BOM. Their knowledge of materials science, manufacturing processes, and technical standards is essential for creating an accurate and comprehensive BOM.

Role of Designers in BOM Preparation

Designers contribute to the preparation of a BOM by providing detailed design specifications, CAD drawings, and product requirements. They are responsible for specifying the dimensions, shapes, materials, and finishes of components, as well as any special features or functionalities required for the product. Designers work closely with engineers to ensure that the design intent is accurately reflected in the BOM, that all components are properly identified and described, and that the product can be manufactured according to the design specifications. Their creative input and attention to detail are crucial for developing a comprehensive and accurate BOM.

Role of Production Planners in BOM Preparation

Production planners play a critical role in preparing a BOM by coordinating the production schedule, material requirements, and assembly processes. They are responsible for translating the BOM into actionable production plans, determining the sequence of operations, and scheduling resources to meet production deadlines. Production planners work closely with engineers and designers to understand the technical requirements of the product, the lead times for materials and components, and the production capacity of the manufacturing facility. Their expertise in production scheduling, resource allocation, and inventory management is essential for creating an efficient and cost-effective BOM.

Components of a Bill of Materials (BOM)

Part Number

The part number is a unique identifier assigned to each component or material listed in the Bill of Materials (BOM). Part numbers help in tracking and referencing components throughout the manufacturing process. They serve as a key identification tool for inventory management, production planning, and quality control. Part numbers are typically alphanumeric codes that are specific to each component, ensuring that no two parts have the same identifier. By using part numbers, manufacturers can easily locate, track, and reorder components as needed during production.

Description

The description of each component or material in the BOM provides detailed information about its characteristics, properties, and functions. Descriptions help in clarifying the purpose and role of each part in the manufacturing process. They include information such as size, shape, material composition, color, and any relevant specifications that define the component. Descriptions are essential for ensuring that the right components are selected, ordered, and used during production. Clear and accurate descriptions help in preventing confusion, errors, and misunderstandings that can lead to production delays or quality issues.

Quantity

The quantity specified in the BOM indicates the required amount of each component or material needed for production. Quantities help in determining how many units of a particular component are needed to assemble the final product. They are typically specified in standard units of measure, such as pieces, kilograms, meters, or liters, depending on the nature of the component. Quantities are essential for accurate production planning, inventory management, and cost estimation. By specifying the exact quantities of materials needed, manufacturers can ensure that they have sufficient stock on hand to meet production demands and avoid shortages or excess inventory.

Unit of Measure

The unit of measure in the BOM specifies the standard unit in which the quantity of each component is measured. This could be pieces, kilograms, meters, liters, or any other relevant unit, depending on the type of component. The unit of measure helps in standardizing the quantity calculations and ensuring consistency in material usage. It also facilitates accurate inventory management and procurement processes by specifying how materials are ordered, stored, and used in production. Having a clear unit of measure for each component in the BOM reduces the risk of errors and confusion in determining the quantities needed for production.

Reference Designators

Reference designators are identifiers that link components in the BOM to their physical locations on the product. They help in identifying where each component should be placed or installed during the assembly process. Reference designators are typically alphanumeric codes or labels that correspond to specific locations on the product, such as PCBs (Printed Circuit Boards), wiring diagrams, or mechanical assemblies. By using reference designators, manufacturers can ensure that components are correctly installed in the right positions, reducing assembly errors and improving production efficiency. Reference designators are essential for facilitating assembly tasks, troubleshooting issues, and maintaining consistency in product assembly.

Suppliers

Information about suppliers or vendors is included in the BOM to identify the sources from which each component or material is obtained. Supplier details help in managing the procurement process, ensuring that materials are sourced from reliable and approved suppliers. By specifying the suppliers for each component, manufacturers can track the origin of materials, maintain quality standards, and establish relationships with preferred suppliers. Supplier information in the BOM also helps in price negotiations, lead time management, and supply chain optimization. Having clear supplier details in the BOM enables manufacturers to build strategic partnerships and ensure a consistent supply of high-quality materials for production.

How to Create BOMs

Creating a Bill of Materials (BOM) involves several steps to ensure accuracy and completeness:

Step 1: Gather Information

The first step in creating a BOM is to gather all relevant information about the product, including design specifications, materials, components, and assembly instructions. This involves collaborating with design, engineering, and production teams to collect data on the requirements and specifications of the product. By gathering comprehensive information upfront, manufacturers can create a detailed and accurate BOM that reflects the intended design and functionality of the product.

Step 2: Organize Components

Once the information is gathered, the next step is to organize the components into logical categories based on their function, relationship, or assembly sequence. This involves grouping similar components, identifying sub-assemblies, and structuring the BOM in a hierarchical format. Organizing components helps in visualizing the product structure, understanding the relationships between different parts, and simplifying the assembly process. By organizing components effectively, manufacturers can streamline production workflows, optimize assembly tasks, and improve overall production efficiency.

Step 3: Identify Relationships

In this step, manufacturers need to identify the relationships between components to understand how they interact and come together to form the final product. This involves determining the assembly sequence, dependencies between components, and any hierarchical structures within the BOM. By identifying relationships, manufacturers can ensure that components are assembled in the correct order, that all necessary parts are included, and that any sub-assemblies are properly integrated into the final product. Understanding the relationships between components is crucial for maintaining product integrity, functionality, and quality.

Step 4: Assign Part Numbers

Assigning unique part numbers to each component in the BOM is essential for tracking, referencing, and identifying parts throughout the production process. Part numbers help in distinguishing between different components, avoiding confusion, and streamlining inventory management. This step involves creating a systematic numbering system that is easy to understand and follow. Part numbers should be unique, standardized, and consistent across all components to ensure accurate identification and tracking. By assigning part numbers, manufacturers can efficiently manage their inventory, track production progress, and facilitate communication among team members.

Step 5: Create Documentation

Documentation plays a critical role in creating a BOM by capturing all the information related to each component, including descriptions, quantities, specifications, and supplier details. This step involves documenting each component’s properties, characteristics, and requirements in a clear and structured format. Detailed documentation ensures that all relevant information is captured accurately, facilitating production planning, procurement, and quality control. Manufacturers should maintain comprehensive records of each component’s details to ensure consistency, traceability, and compliance with standards and regulations.

Step 6: Review and Validate

Before finalizing the BOM, manufacturers need to review and validate the list to ensure its accuracy and completeness. This step involves cross-checking component details, verifying quantities, confirming supplier information, and validating the overall structure of the BOM. Manufacturers should involve key stakeholders, such as engineers, designers, and production planners, in the review process to identify any discrepancies or issues. By conducting a thorough review and validation, manufacturers can catch any errors or omissions early on, preventing costly mistakes and ensuring that the BOM is ready for production.

Step 7: Update as Needed

As the product evolves or new components are introduced, it is essential to update the BOM to reflect any changes. This step involves maintaining the BOM as a living document that is continuously updated to align with product revisions, design modifications, or new requirements. Manufacturers should establish a change management process to track and document any updates to the BOM. By updating the BOM as needed, manufacturers can ensure that production processes remain efficient, accurate, and compliant with the latest design specifications. Regularly updating the BOM helps in maintaining product quality, reducing errors, and enhancing overall production performance.

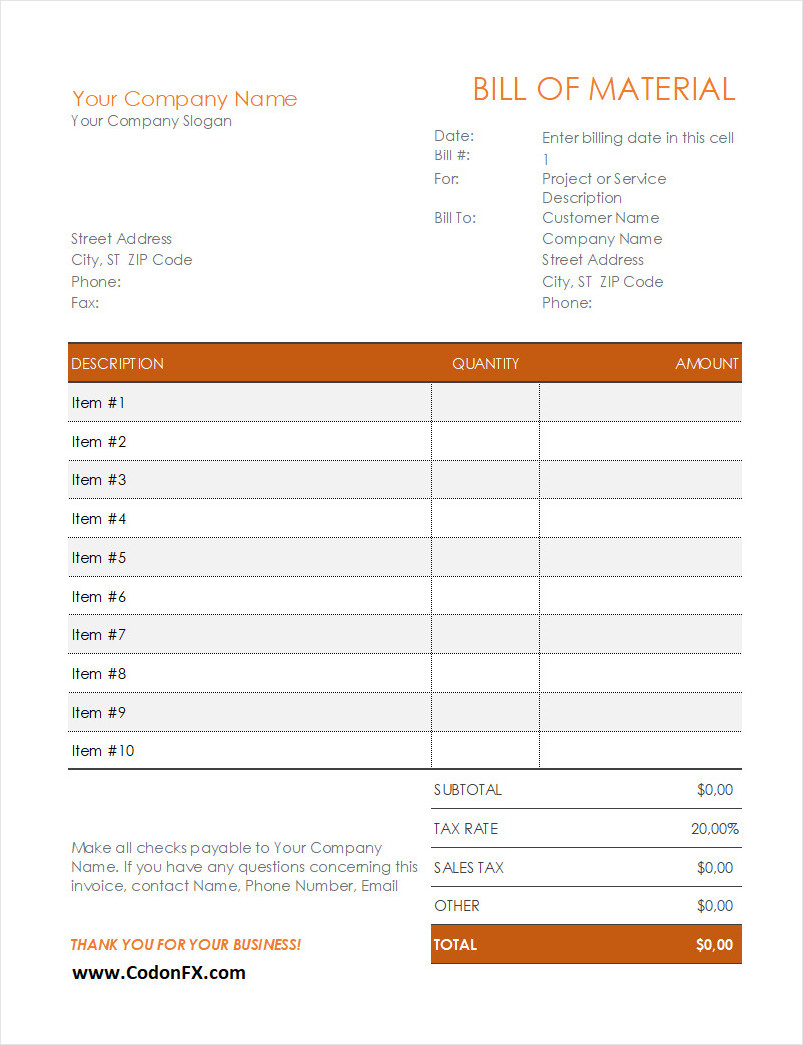

Bill of Material Template

A bill of material template is a valuable tool for listing all parts, components, and materials required to complete a project or product. It helps improve accuracy, streamline production, and keep costs under control.

To simplify project planning and inventory management, use our free bill of material template and organize your materials with ease!

Bill of Material Template – Excel