Keeping track of inventory is crucial for any business, whether you’re a small retailer or a large-scale manufacturer. An inventory checklist helps you maintain control over your stock, prevent shortages, and ensure that your products are always available to meet customer demand.

In this comprehensive guide, we’ll walk you through everything you need to know about creating and managing an inventory checklist.

What is an Inventory Checklist?

An inventory checklist is a tool used to track and manage the stock of goods or materials within a business. It provides a detailed record of the items in stock, including their quantities, locations, and other relevant information. By regularly updating and reviewing the checklist, businesses can ensure that they have adequate inventory levels to meet customer demands and avoid unnecessary expenses.

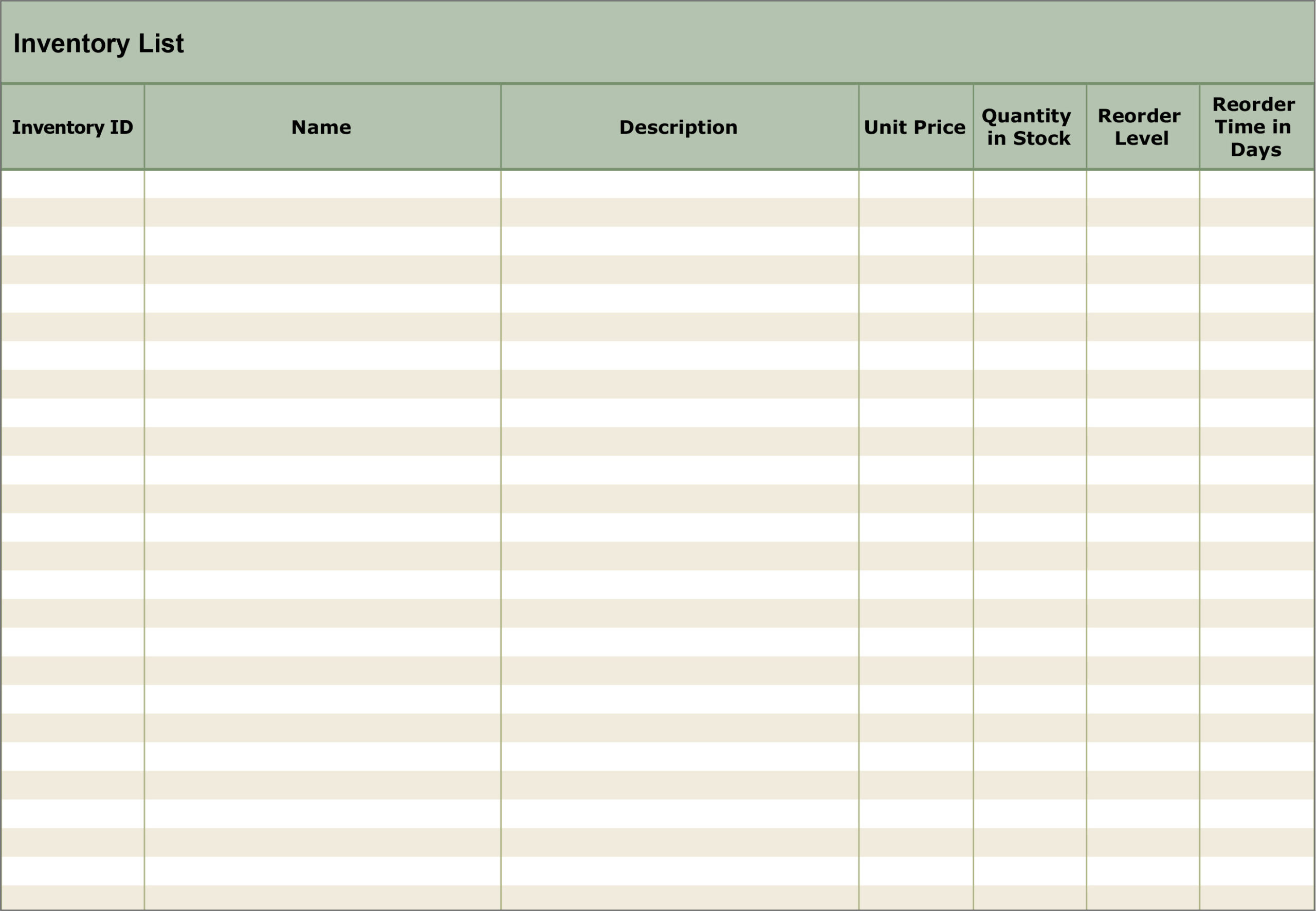

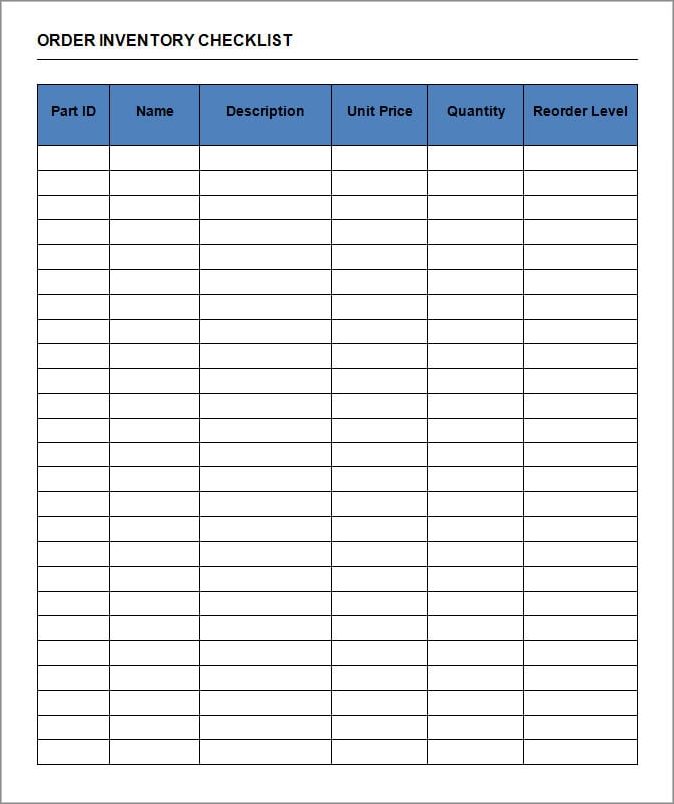

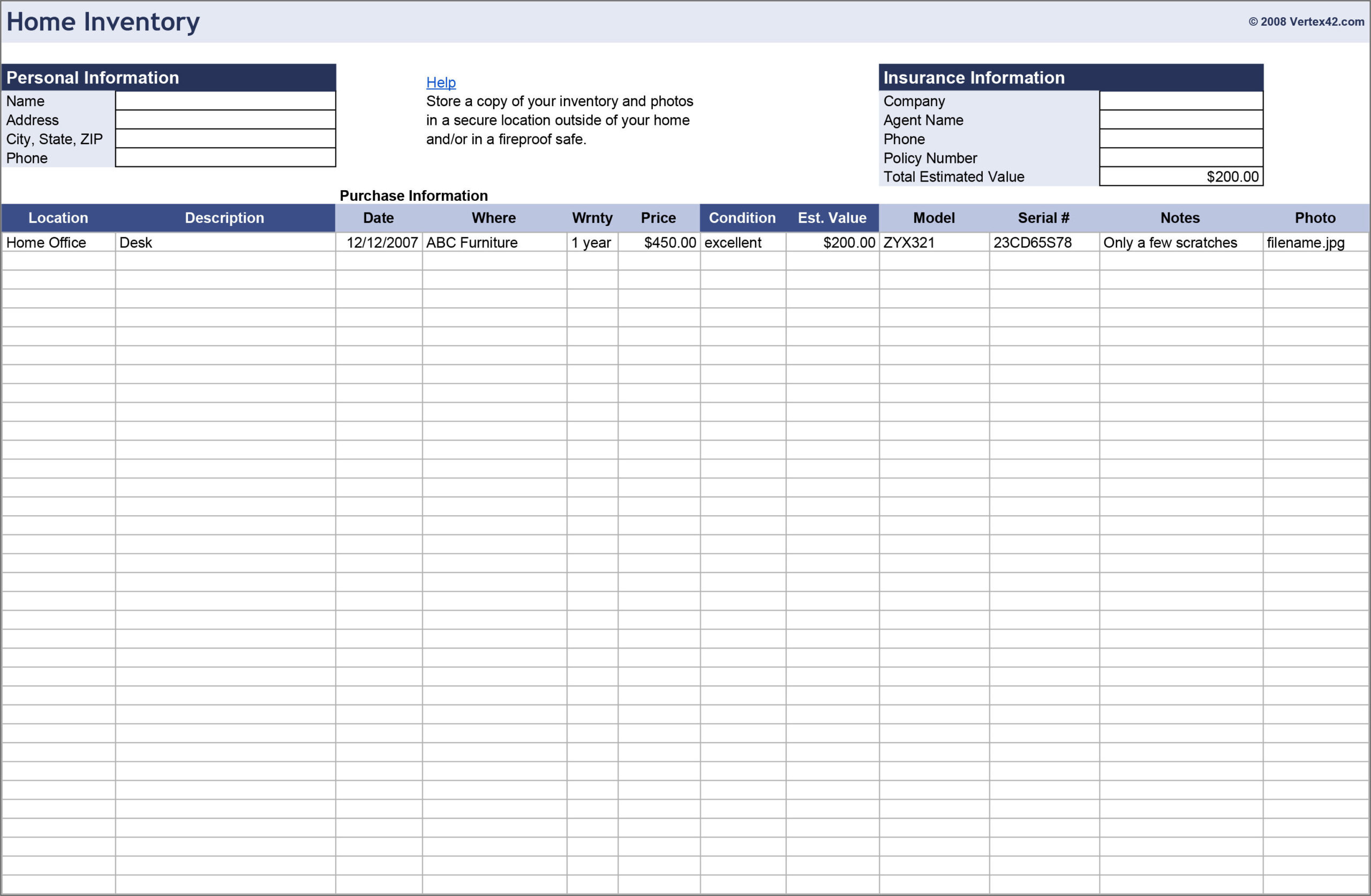

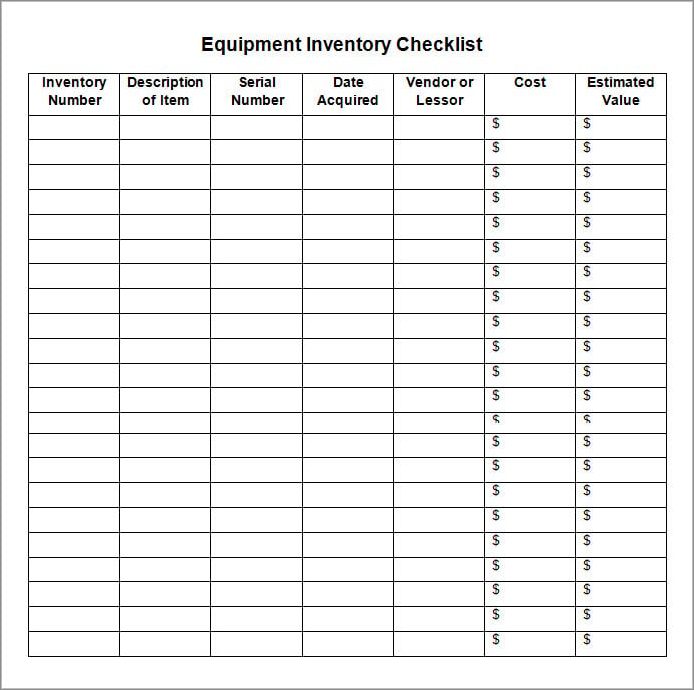

An inventory checklist can be created using various methods, such as manual record-keeping or using specialized inventory management software. Regardless of the method, the checklist should include essential details about each item, such as the item name, SKU or barcode, unit cost, quantity on hand, reorder point, and supplier information.

Why Do You Need an Inventory Checklist?

An inventory checklist is essential for several reasons:

- Preventing Stockouts: By regularly reviewing your inventory checklist, you can identify items that are running low and reorder them before they run out completely. This helps prevent stockouts, ensuring that you always have the products your customers want.

- Reducing Excess Inventory: On the other hand, an inventory checklist can also help you identify items that have excessive stock levels. By monitoring these items, you can adjust your ordering patterns and reduce excess inventory, freeing up capital for other business needs.

- Improving Cash Flow: By optimizing your inventory levels, you can improve cash flow by reducing tied-up capital and lowering the risk of obsolete or expired stock.

- Streamlining Operations: An inventory checklist enables you to have a clear view of your stock levels and locations. This information allows you to streamline your warehouse operations, making it easier to pick, pack, and ship orders efficiently.

- Enhancing Customer Satisfaction: By having the right products in stock and readily available, you can meet customer demands promptly, leading to higher customer satisfaction and loyalty.

How to Create an Inventory Checklist

Creating an inventory checklist may seem overwhelming, but it can be broken down into a few simple steps:

1. Determine the Scope of Your Inventory

Start by identifying the scope of your inventory. Determine which items you want to include in your checklist, whether it’s all your products, specific product categories, or materials used in production.

2. Choose a Method of Tracking

Decide how you will track your inventory. You can use manual methods, such as spreadsheets or physical count sheets, or leverage technology with inventory management software.

3. Collect Essential Information

Gather all the necessary information about each item in your inventory. This includes item names, SKUs or barcodes, unit costs, quantities, reorder points, supplier information, and any other relevant details.

4. Organize Your Checklist

Organize your checklist in a logical manner, such as by product category or location. This will make it easier to find and update information quickly.

5. Establish a Regular Review Schedule

Set a regular schedule for reviewing and updating your inventory checklist. This ensures that you always have accurate and up-to-date information.

6. Train Your Staff

If you have employees responsible for managing inventory, make sure they are trained on how to use the checklist and understand the importance of accurate record-keeping.

Best Practices for Managing Your Inventory Checklist

To get the most out of your inventory checklist, consider implementing the following best practices:

- Regularly Update Your Checklist: Make it a habit to update your inventory checklist as soon as any changes occur, such as receiving new stock or selling items.

- Conduct Physical Counts: Regularly perform physical counts to verify the accuracy of your inventory records. This helps identify any discrepancies and allows for necessary adjustments.

- Implement a Reorder Point System: Set reorder points for each item on your checklist to ensure that you replenish stock before it runs out. This helps prevent stockouts and keeps your inventory levels optimized.

- Integrate with Your POS System: If you have a point-of-sale (POS) system, integrate it with your inventory checklist to automatically update stock levels as sales are made.

- Regularly Analyze Inventory Data: Use inventory reports generated from your checklist to analyze trends, identify slow-moving items, and make informed purchasing decisions.

- Ensure Security and Accuracy: Protect your inventory checklist from unauthorized access and ensure the accuracy of data by implementing security measures, such as user restrictions and regular backups.

Conclusion

An inventory checklist is an invaluable tool for any business that deals with physical products or materials. By creating and regularly updating your checklist, you can effectively manage your inventory, prevent stockouts, reduce excess stock, improve cash flow, and ultimately enhance customer satisfaction. Remember to choose a tracking method that suits your business needs, train your staff, and follow best practices to make the most out of your inventory management efforts.

Inventory Checklist Template Excel – Download